How to Seal Glass Milk Bottle? 4 Easy Steps!

For an effective and secure seal on your glass milk bottles, it’s important to follow a few key steps.

Begin by selecting a high-quality sealant that is suitable for food contact and can handle the temperature changes typical to milk storage.

Once you have your sealant, clean the bottle and cap thoroughly to remove any residue or debris.

Apply the sealant according to the manufacturer’s instructions, ensuring a tight fit between the bottle and the cap.

Allow the sealant to cure if necessary before testing the seal by gently shaking the bottle.

With these steps, your milk will remain fresh and contained without any mess in your refrigerator.

Here are some quick steps:

For example, if you choose a silicone sealant, you would apply it around the rim of the bottle before screwing on the cap. After letting it dry for the recommended time, you shake the bottle to check for leaks.

Ensure your milk stays fresh and your fridge clean by mastering the simple yet effective technique of sealing glass milk bottles.

Key Takeaway

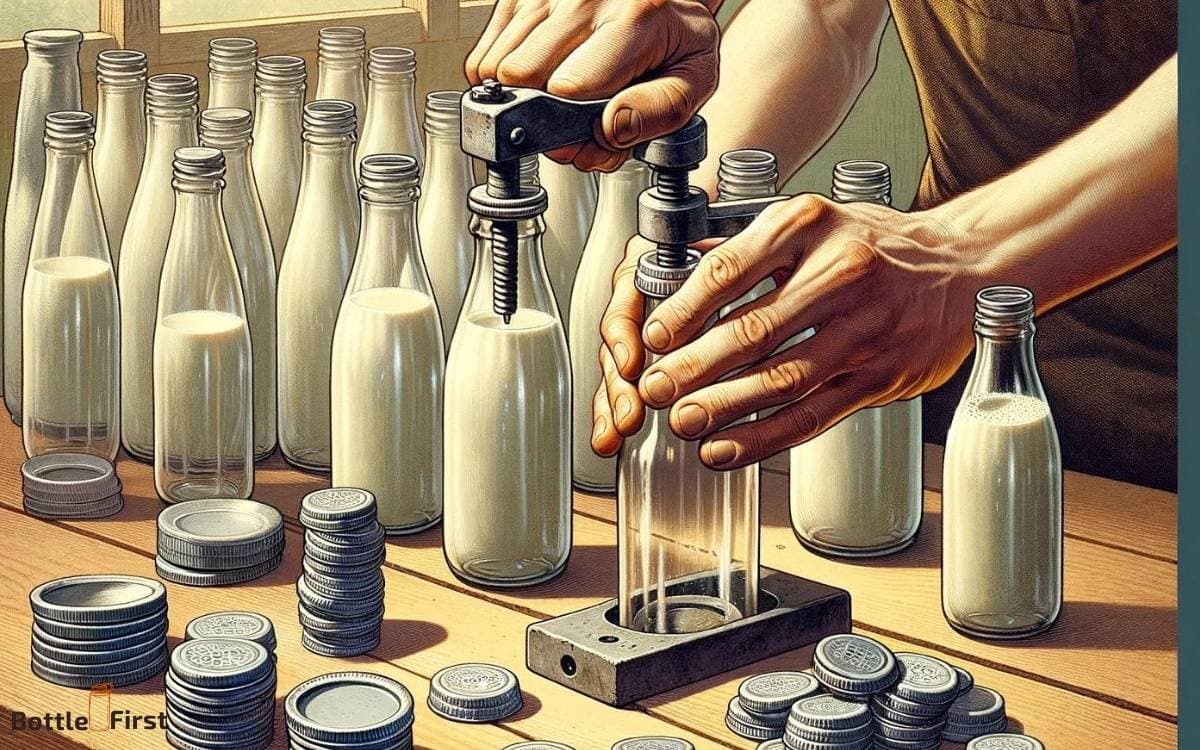

Step 1: Choosing the Right Sealant

When sealing a glass milk bottle, start by assessing the type of sealant suitable for your specific needs and the intended use of the bottle.

Consider factors such as the temperature at which the bottle will be stored, the potential for exposure to sunlight, and the frequency of opening and closing the bottle.

For a durable and long-lasting seal, consider using a silicone-based sealant that can withstand a wide range of temperatures and provides a strong barrier against moisture and air.

Alternatively, if the bottle will be frequently opened and closed, a more flexible sealant such as a rubber-based one might be more suitable.

Innovations in sealant technology have led to the development of options that offer superior adhesion and resilience, ensuring that your glass milk bottle remains tightly sealed and protected.

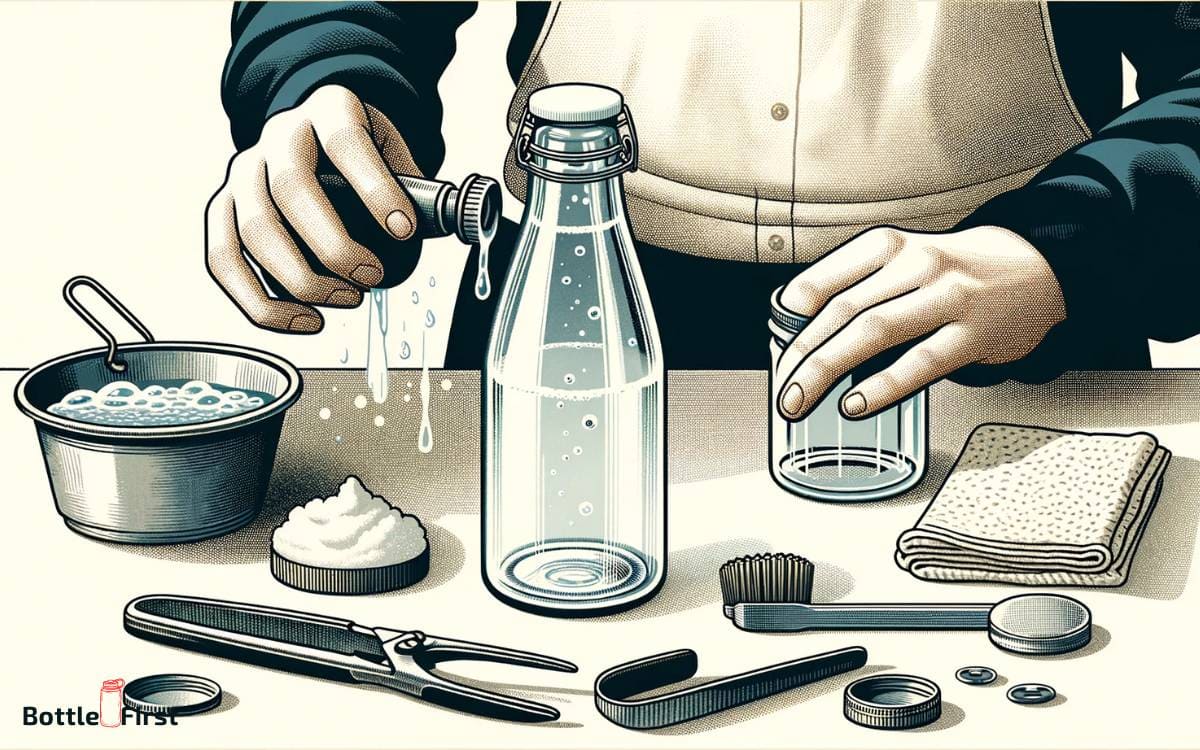

Step 2: Preparing the Bottle and Cap

To prepare the bottle and cap for sealing, start by thoroughly cleaning both with warm, soapy water and allowing them to dry completely before applying the sealant.

Use a gentle scrubbing brush to remove any residue or build-up on the glass surface. Ensure that no soap or water remains inside the bottle or cap before proceeding.

Next, inspect the bottle and cap for any cracks, chips, or defects that may affect the sealing process. It’s crucial to address any imperfections before proceeding.

Additionally, make sure the cap threads are clean and free from any debris. This will ensure a secure and effective seal.

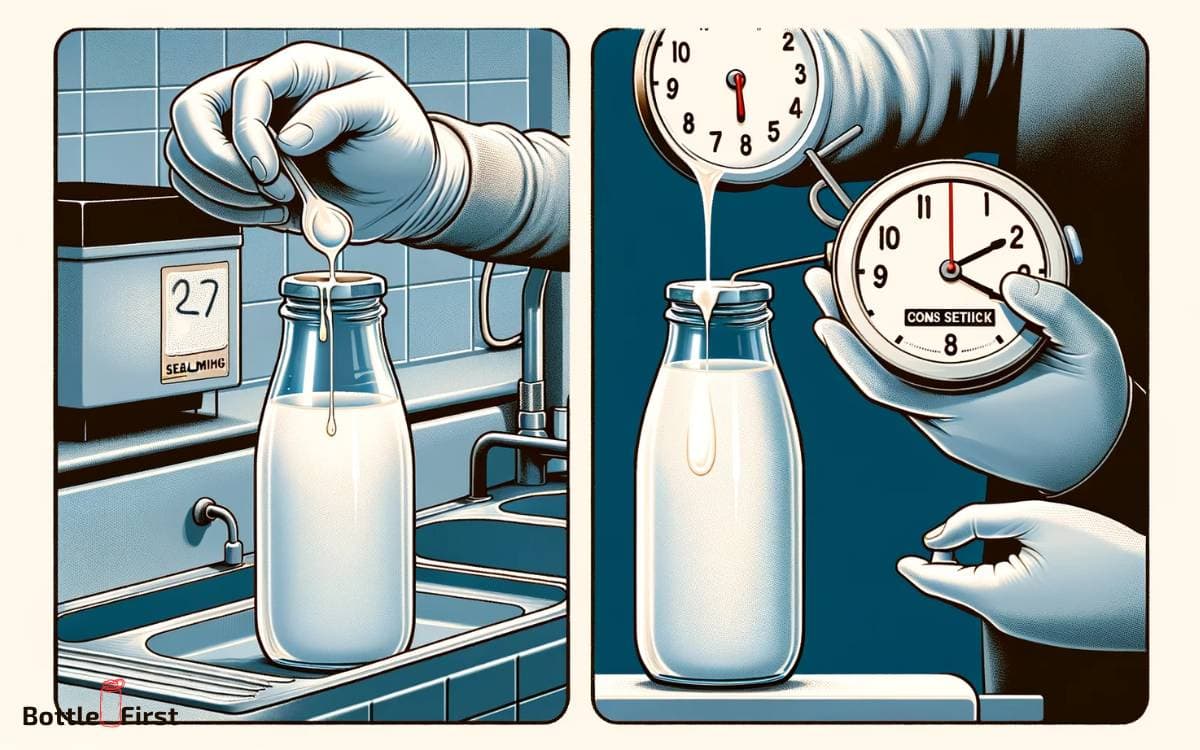

Step 3: Applying the Sealant

After preparing the bottle and cap, proceed by carefully applying the sealant to ensure a tight and secure closure.

To apply the sealant effectively, follow these steps:

- Clean the rim of the bottle and the inner side of the cap with a lint-free cloth to remove any dust or residue.

- Apply a thin, even layer of the sealant around the rim of the bottle. Be sure to cover the entire circumference to create a complete seal.

- Place the cap onto the bottle and twist it tightly to evenly distribute the sealant and ensure a snug fit.

- Wipe away any excess sealant that may have squeezed out from under the cap to prevent it from hardening and affecting the closure.

- Allow the sealant to cure for the recommended time before testing the seal for tightness and security.

With the sealant applied, the next step is to ensure its effectiveness by curing and testing the seal.

Step 4: Curing and Testing the Seal

To cure and test the seal of the glass milk bottle, carefully inspect the cap for any signs of leakage or looseness.

Once the sealant has been applied and the cap secured, allow the bottle to cure for the recommended time as per the sealant manufacturer’s instructions.

After the curing period, it’s time to test the seal. Gently press down on the cap to ensure it’s firmly in place.

Then, fill the bottle with water and carefully tip it in different directions to check for any leaks. If any leaks or looseness are detected, reapply the sealant and repeat the curing process.

A properly sealed bottle should show no signs of leakage or looseness. With the seal cured and tested, you can now move on to the next steps for maintenance and storage.

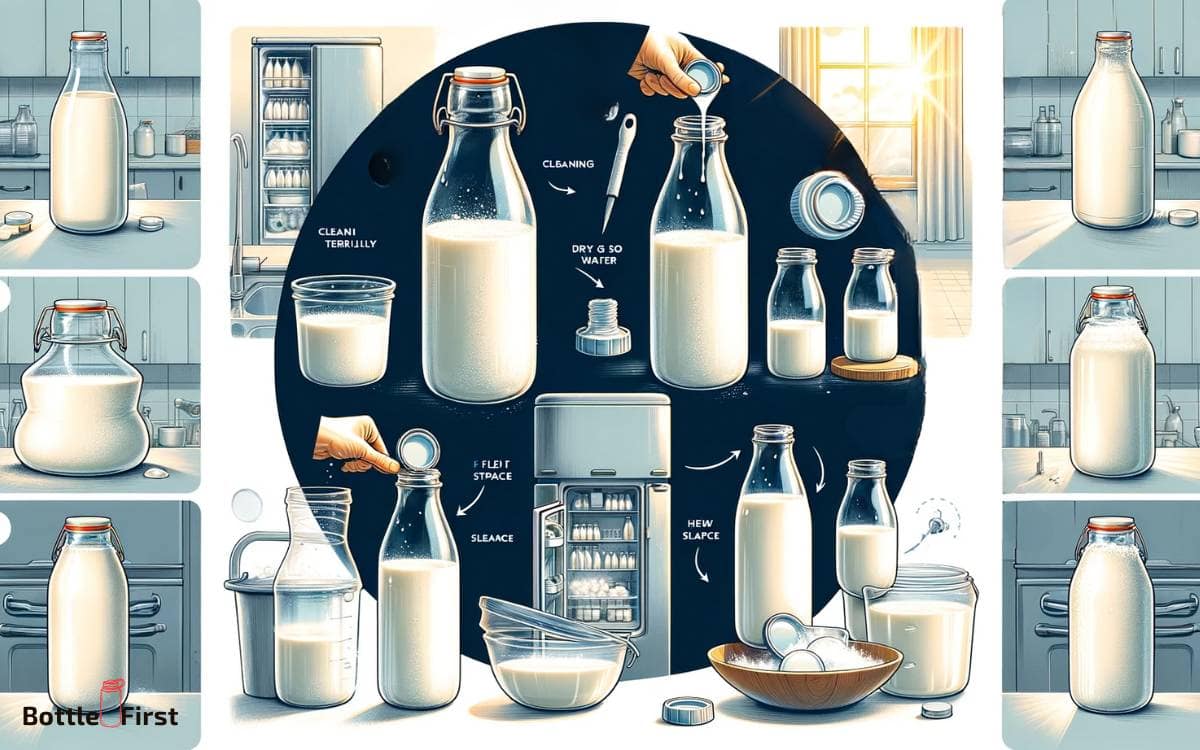

Maintenance and Storage

Once you have cured and tested the seal of the glass milk bottle, it’s time to move on to maintenance and storage while ensuring the bottle is securely sealed for long-term use.

To maintain and store the glass milk bottle properly, follow these key steps:

- Clean the bottle regularly with mild soap and water to prevent the buildup of residue or bacteria.

- Inspect the seal periodically for any signs of wear or damage, and reseal if necessary using the same sealing process.

- Store the bottle in a cool, dry place away from direct sunlight to preserve the quality of the milk and the seal.

- Avoid sudden temperature changes, as extreme heat or cold can affect the integrity of the seal.

- Use the milk within a reasonable time frame to ensure freshness and to minimize the need for prolonged storage.

Following these maintenance and storage practices will help keep your glass milk bottle sealed and in optimal condition for an extended period.

Conclusion

After following these steps, you have successfully sealed your glass milk bottle, ensuring its contents remain fresh and secure.

Just like a well-protected treasure, your milk will be safe from any external elements. With proper maintenance and storage, your sealed bottle will continue to serve its purpose effectively.

Now, enjoy the peace of mind knowing that your milk will stay fresh for longer.