How Much Does It Cost to Make a Water Bottle? Find Out Here!

The cost to manufacture a water bottle varies widely, depending on factors such as materials, production scale, and brand.

On average, a single-use plastic water bottle costs between $0.05 to $0.25 to produce. Reusable bottles, like stainless steel or glass, can cost anywhere from $2 to $15 to manufacture.

The production cost of a water bottle is influenced by:

For instance, a single-use PET bottle will be cheaper due to low-cost materials and mass production, while a high-end branded reusable bottle will cost more due to premium materials and additional features.

Understanding water bottle production costs sheds light on consumer pricing and environmental impacts, emphasizing the value of informed choices.

Key Takeaway

Materials Cost Breakdown

You can expect that about 70% of the cost to make a water bottle is attributed to the materials used in its production.

This means that the majority of the expenses are tied to acquiring the raw materials necessary for creating the bottle.

The primary materials used in making water bottles include plastic, glass, or metal, along with the caps and labels. The cost of these materials can vary based on factors such as quality, quantity, and sourcing.

Additionally, the cost of transportation and storage of these materials adds to the overall expenditure.

Understanding the breakdown of material costs can help in making informed decisions about sourcing, production processes, and overall budgeting.

By managing these costs effectively, you can ensure the sustainability and affordability of producing water bottles.

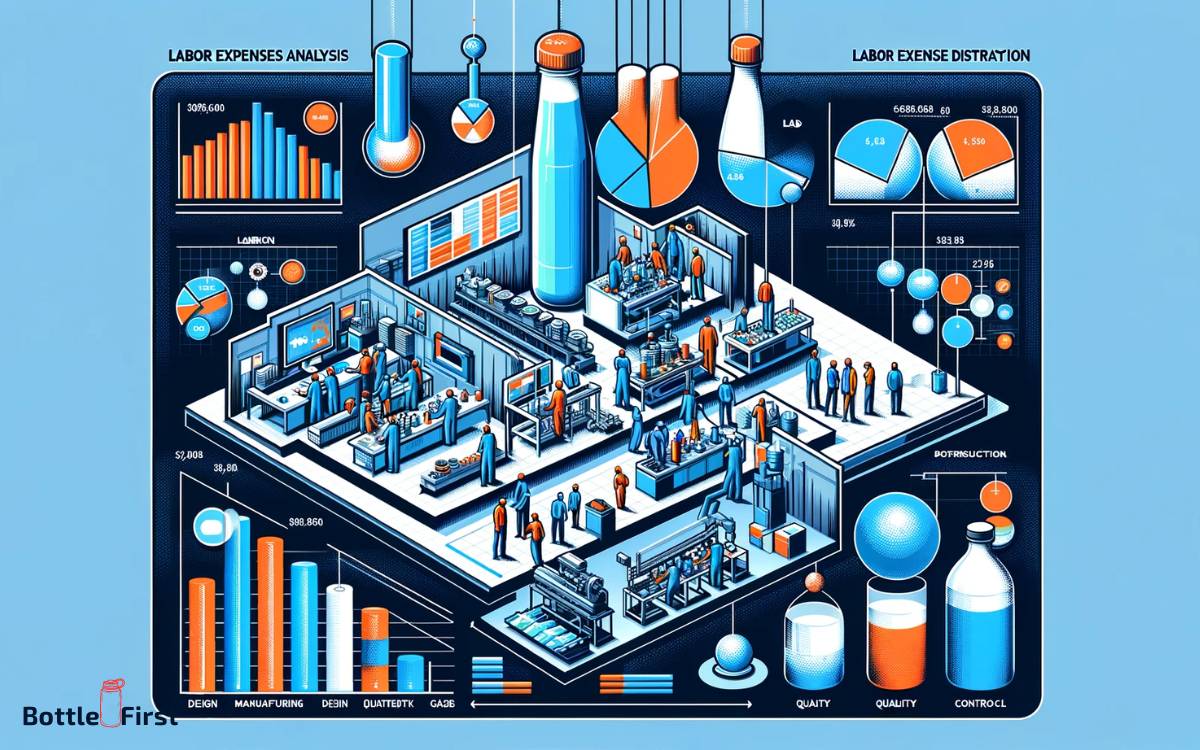

Labor Expenses Analysis

Analyzing labor expenses for making water bottles involves evaluating the costs associated with the human effort required to manufacture, assemble, and package the bottles. This analysis builds on the understanding of material costs.

Labor expenses encompass wages, benefits, training, and supervision for the skilled workers involved in the production process.

It’s crucial to determine the optimal balance between automation and manual labor to minimize costs while maintaining product quality.

Efficient production line layouts and streamlined processes can also contribute to reducing labor expenses.

Additionally, continuous improvement initiatives and employee engagement programs can enhance productivity, further impacting labor costs.

Understanding and managing labor expenses are essential for optimizing the overall production cost and ensuring the competitiveness of your water bottle manufacturing operation.

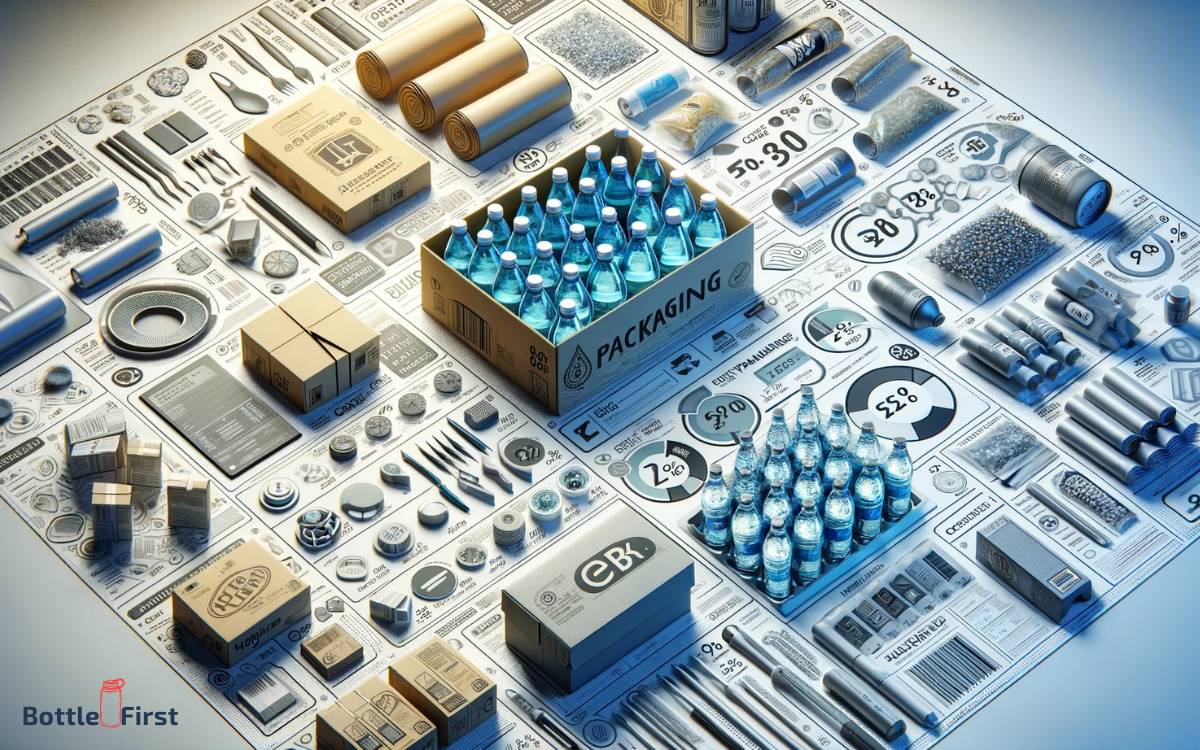

Packaging and Labeling Costs

When considering packaging and labeling costs, it’s essential to carefully assess the impact on the overall production expenses.

Here are some key points to consider:

- Material Selection: Opt for cost-effective yet durable materials to ensure the safety and integrity of your water bottles.

- Design and Printing: Invest in appealing and informative labels that comply with industry regulations while staying true to your brand identity.

- Labor and Machinery: Factor in labor and machinery costs for packaging and labeling processes, ensuring efficiency and quality control.

- Packaging Efficiency: Explore innovative packaging designs to minimize material waste and optimize storage and transportation.

As you assess these aspects, it’s important to transition into the subsequent section about ‘transportation and distribution charges’ to gain a comprehensive understanding of the total production expenses.

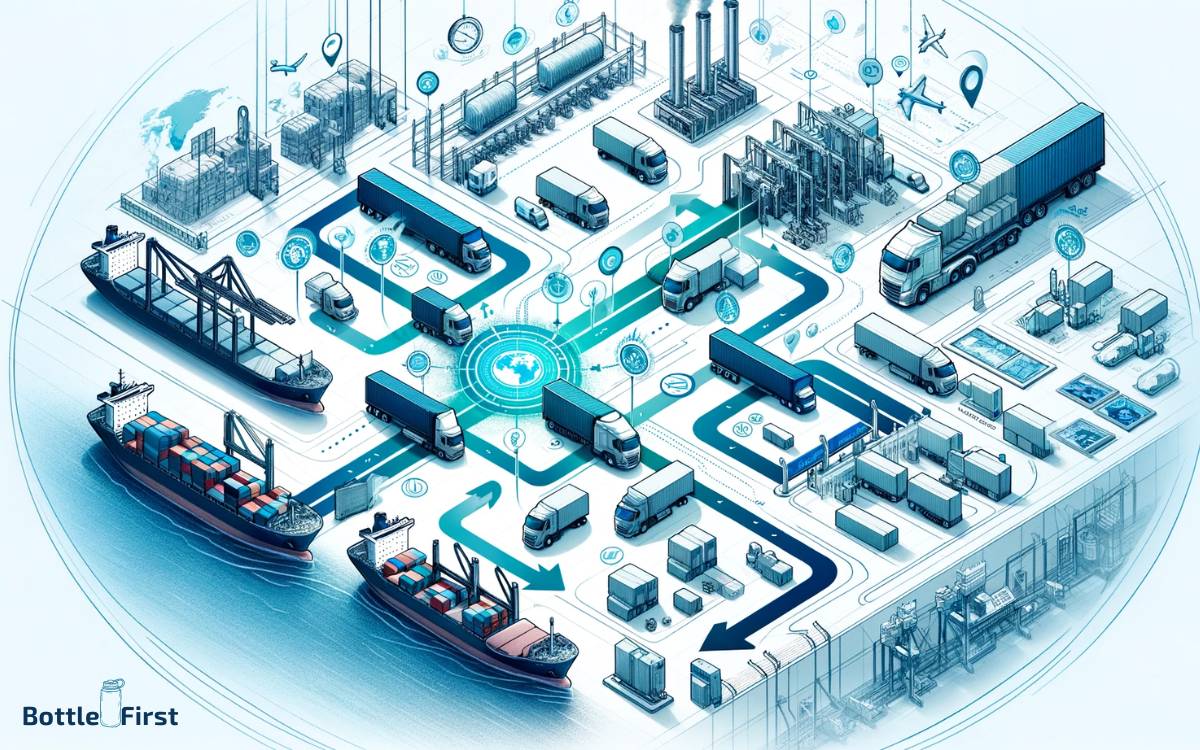

Transportation and Distribution Charges

Considering the impact on overall production expenses, the transportation and distribution charges for water bottles play a crucial role in determining the final cost.

These charges encompass the cost of moving the bottles from the manufacturing facility to distribution centers and then to retailers, as well as any associated handling and storage fees.

Additionally, factors such as fuel prices, distance traveled, and transportation modes significantly influence these expenses.

To better understand the impact of transportation and distribution charges, let’s take a look at the following table:

| Transportation Mode | Distance Traveled (miles) | Average Cost ($) |

|---|---|---|

| Truck | 500 | 600 |

| Rail | 500 | 400 |

| Ship | 1000 | 800 |

These charges are critical in determining the final price of a water bottle and can vary depending on the transportation mode and distance traveled. Understanding these costs is essential in accurately assessing the total production expenses.

Total Cost Calculation

To calculate the total cost of making a water bottle, you need to factor in various expenses, including production, materials, and transportation and distribution charges.

Consider the following:

- Production costs, including labor, machinery, and overhead expenses

- Material costs for the bottle and cap, such as plastic or glass

- Energy costs for the manufacturing process, including heating and cooling

- Packaging costs, including labeling, boxing, and protective materials

Understanding these expenses is crucial for determining the overall cost of producing a water bottle.

By analyzing each component, you can gain a comprehensive understanding of the total cost, allowing for informed decisions regarding pricing and profitability.

Conclusion

In the end, the cost of making a water bottle is more than just dollars and cents. It symbolizes the resources, effort, and care that go into creating something essential for life.

Each bottle represents the journey from raw materials to the hands of the consumer, reminding us of the value of every drop of water and the responsibility to use and reuse resources wisely.