Tips, Reviews, Guides, and How-to’s for Bottles

The best way to find your new favorite bottle!

New Bottle Contents

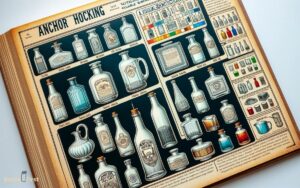

What We Follow at BottleFirst

Research on Web

Hands-On Testing

Data-Driven Reviews

BottleFirst Feature

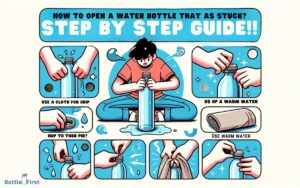

Water Bottle

Dive into Our Water Bottle Feature for Hydration Perfection

Blender Bottle

Uncover the Magic of Blender Bottles in Our Exclusive Feature

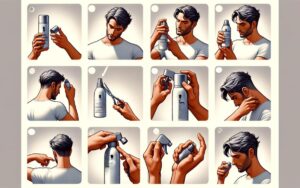

Spray Bottle

Explore the Versatility of Spray Bottles in Our Latest Highlight

Baby Bottle

Discover the Finest Baby Bottles for Your Little One in Our Special Feature

Glass Bottle

Get Acquainted with Elegant Glass Bottles in Our Curated Showcase

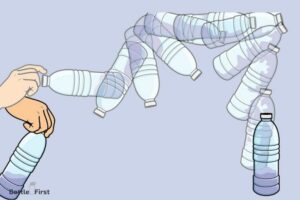

Bottle DIY

Unleash Your Imagination with Our Fun and Easy Bottle DIY Ideas!